Healthcare with Confidence

New achievements of Israeli researchers in 3d medical implants printing gave surgeons more freedom to retain surrounding healthy tissue and optimize reconstruction fit, thereby improving quality of life and reducing comorbidities post-operatively.

Creating these custom implants has brought forth novel processes, materials and technologies and given rise to a new era in Plastic Surgery, Neurosurgery, Orthopedic Oncology and other fields.

To evaluate the possibility of a surgery using 3D implants printing by an Israeli specialist in your case, please send your medical history, CT or MRI, and a doctor’s report. We will discuss your case preliminarily with the specialists and promptly organize doctor’s appointment and consultation online.

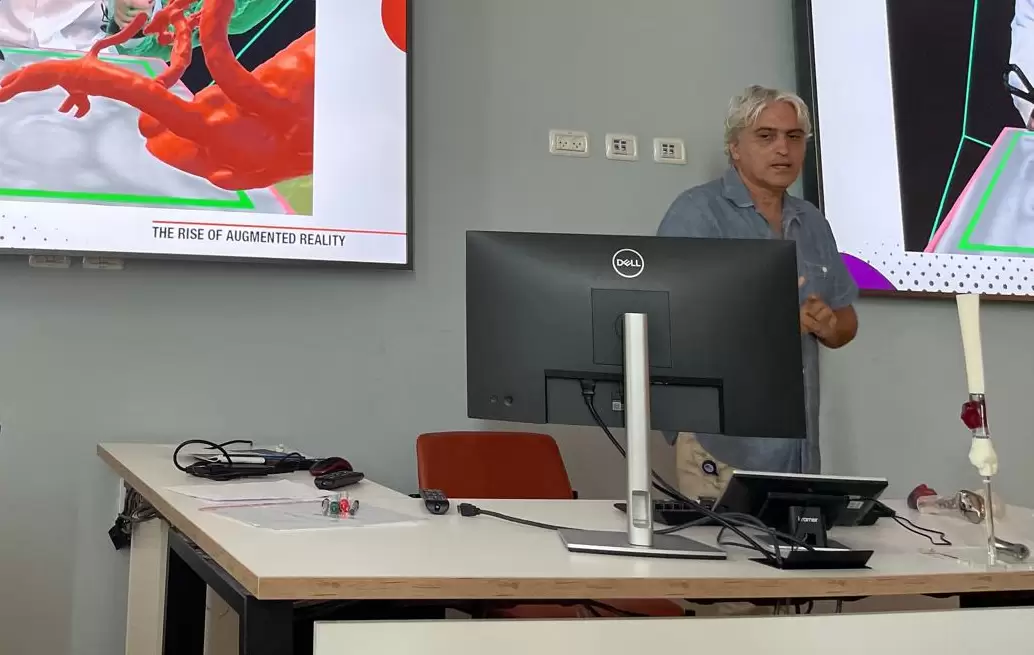

Dr. Dadia Shlomo – an orthopedist and the leading specialist for 3d printed implants in Israel

Dr. Dadia Shlomo – an orthopedist and the leading specialist for 3d printed implants in Israel

Position: Head of the Surgical Innovation Unit, Tel Aviv Medical Center, Ichilov.

Specialty: Specialist in oncological orthopedics and joint, knee and hip replacement.

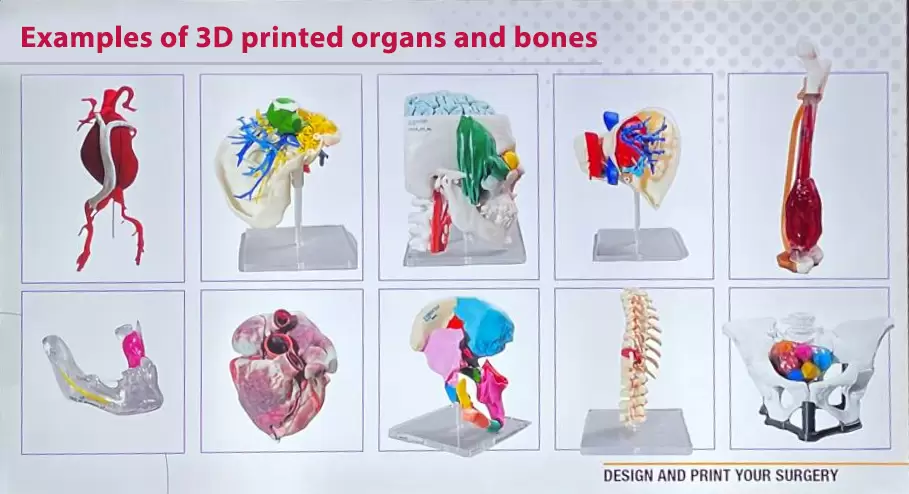

Israeli Surgeons widely use 3D Medical Printing in plastic surgery, where this technology has been increasingly adopted using serializable intraoperative 3D printed models, particularly in scull bone reconstruction for eyes, ears and nose regions. This way it helps to enhance treatment planning and precision. Live bioprinting is also explored, driving innovation in tissue engineering and vascularized composite allotransplantation.

In orthopedic oncology these approaches are widely used with primary bone sarcomas, which are mesenchymal tumors arising from bone and connective tissue are among the more common tumors, with an estimated annual incidence of between 10 and 26 per million people worldwide. The majority of bone sarcomas can be divided into three different types: osteosarcoma, Ewing’s sarcoma and chondrosarcoma, which historically leads to future amputations and life quality.

Weakened bone with such diseases has increased tendency to fracture, as well as systemic symptoms varying from limping in cases with lower limb involvement to unintended weight loss and B-symptoms. It can involve lower limbs, the knee joint and the diaphysis of long bones, pelvis, hips and shoulders. These tumors can either spread directly as skip lesions or metastasize via the blood stream, most often to the lungs.

How Israeli doctors diagnose patients and treat using 3D printing implants

Israeli doctor diagnose primary bone sarcoma using imaging tests such as ultrasound, computed tomography (CT), MRI with gadolinium and whole-body positron emission tomogram-CT (PET-CT), and biopsy for grade determination of disease.

For treatment Surgeons in Israel use radiation, chemotherapy, (neo)-adjuvant therapies and surgery resection of tumor mass with 3D Printing of damaged bone.

It helps to avoid amputations of limbs and improve future quality of life and mobility of the patient.

With the Israeli advancement of treatment and technologies, our surgeons are able to remove the tumor along with the implicated bone, while preserving as much as possible from the remaining limb, using such technologies as:

- intraoperative fluoroscopic imaging

- CT-guided navigation with an O-arm

- optical navigation

- augmented-reality (AR) based navigation

- patient-specific instruments (PSIs)

Creating fully anatomical model for our patients consists of several steps

Image acquisition & processing using CT and MRI imaging

Israeli Radiologists prepare image scanning with high-quality raw data for creating of 3d printed model. Both CT and MRI are commonly used imaging modalities and complement each other for this purpose. Radiologists in Israel get accurate anatomical model by producing thin axial section images or slices with thickness of 1 mm and further post-processing by specialized 3D applications in Israeli laboratory.

Segmentation from 2D to 3D

After getting 2D image body scan from CT or MRI, Our medical engineers in Israel made segmentation, where they are identifying and delineating specific anatomical structures or tissues . During this stage, where different part can be automatically, semi-automatically, or manually, our team separates the relevant structures from the background, creating regions of interest. In the context of 3D modeling, this segmentation provides the basis for creating a 3D representation.

After segmenting the structures from both CT and MRI images, our engineer fuse them together. Fusion combines information from both imaging modalities, enhancing the overall understanding of the anatomy, which are accurately matched in all three axes (x, y, z) to ensure alignment. Other words we get 3D image for next stage.

Printing process

In Israel medical 3D printing is based on an additive manufacturing principle in which thin cross-sectional slices of material such as polymers, metals or ceramics are added one on top of the other and fused together by light, chemical reactions, or varying temperature. At the end of this stage, the various layers are merged into a 3D physical model of new patient implant.

Unique Israeli AM technology allows to create complex geometries as scaffolds (or models), which can contain solid parts interconnected with porous structures. This freedom enables better geometric versatility to create customized implants and sterilized patient-specific instruments (PSIs) and fit exactly to the shape and location required. This advantage proves especially relevant when it is designing customized implants aimed at mimicking the porous mechanical characteristics of human bone. AM technology offers a method to print a physical model that precisely matches the anatomy of a specific patient in terms of weight, color and even consistency.

Surgical Planning

Orthopedic surgeons in Israel, using the 3D models and PSIs, plan and execute precise surgical resections with minimal margins, ensuring complete tumor removal while preserving as much healthy tissue of head or body as possible.

Reconstruction of affected bones in orthopedic oncology

In post-tumor resection period, Israeli surgeons utilizing customized 3D-printed titanium implants to reconstruct the defects, aiming for optimal structural, functional, and aesthetic outcomes for our patients.

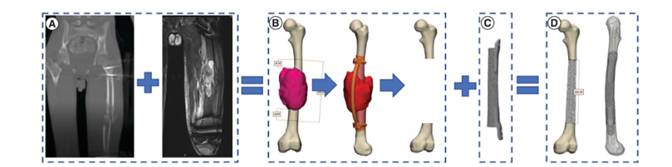

3D medical printing on the example of left femur bone within Ewing Sarcoma

A – MRI and CT scan of affected bone within Ewing sarcoma

B – 3D implant model after image segmentation and fusion

C- Printed physical implant from porous titanium for patient

D – Patient left femur bone with printed implant

These 3d-printed implants can be individually designed precisely for unusual sizes or shapes and has introduced a new era of bone reconstruction options. An such advance as bone regeneration and osteointegration both inside and over the surface of the customized 3D-printed implant, promoting better integration with native bone and reduces the chances for fracture comparable with standard classical approaches.